OEE efficiency

Your unplanned downtime could be having a bigger impact than you think

Get a clearer picture of your efficiency

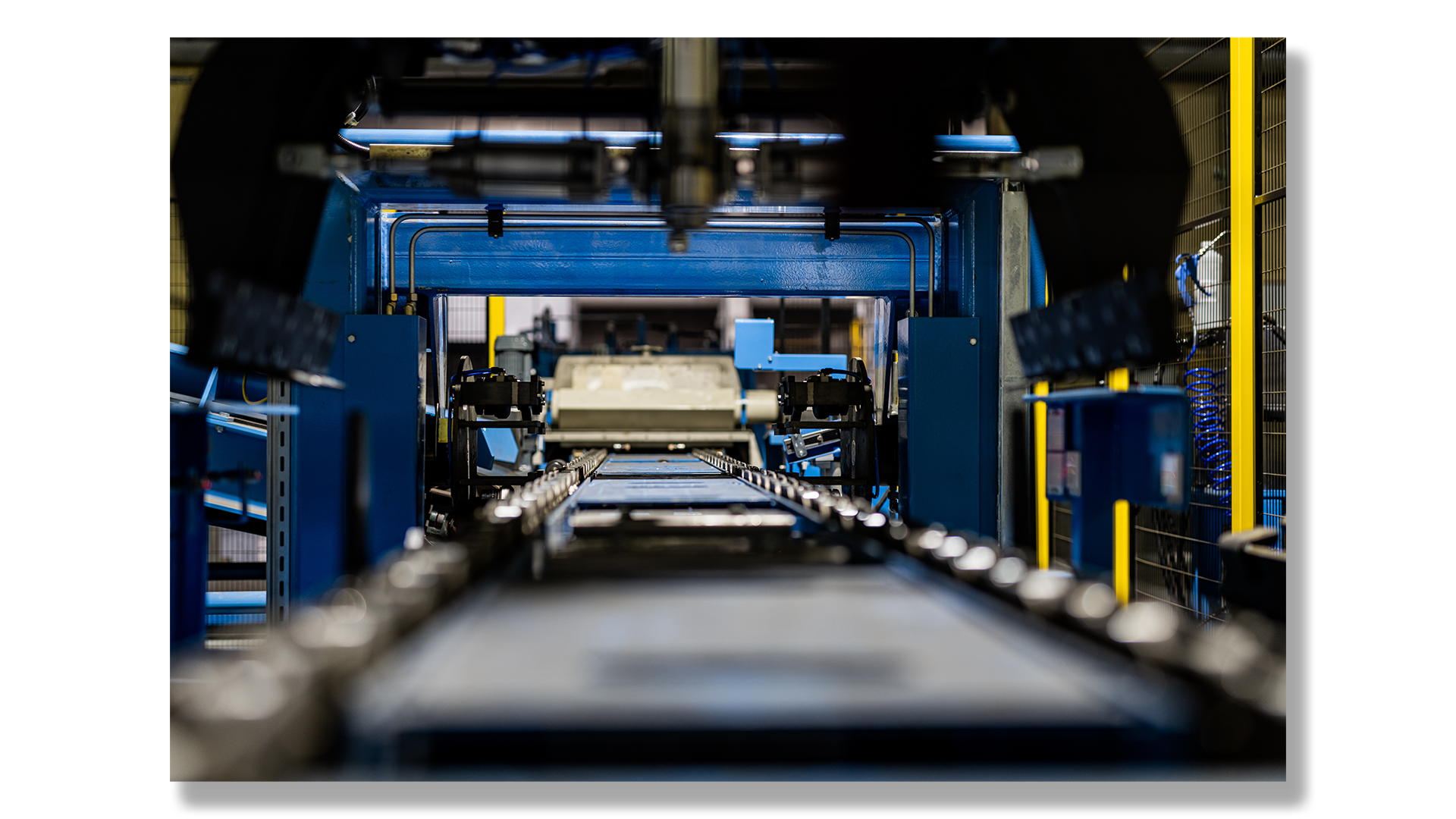

What’s getting in the way of your operation’s true potential?

Put a stop to short stops

Firefighting can mean your operators aren’t fully undertaking their true roles. The time taken to put right short stops adds up to significant levels quickly. Wherever you’re experiencing stoppages in your filling and packing operation, the true problem is visibility. Without an understanding of what causes your short stops, and in turn the overall impact on your operation, these issues will continue to plague your efficiency figures.

The power of visibility

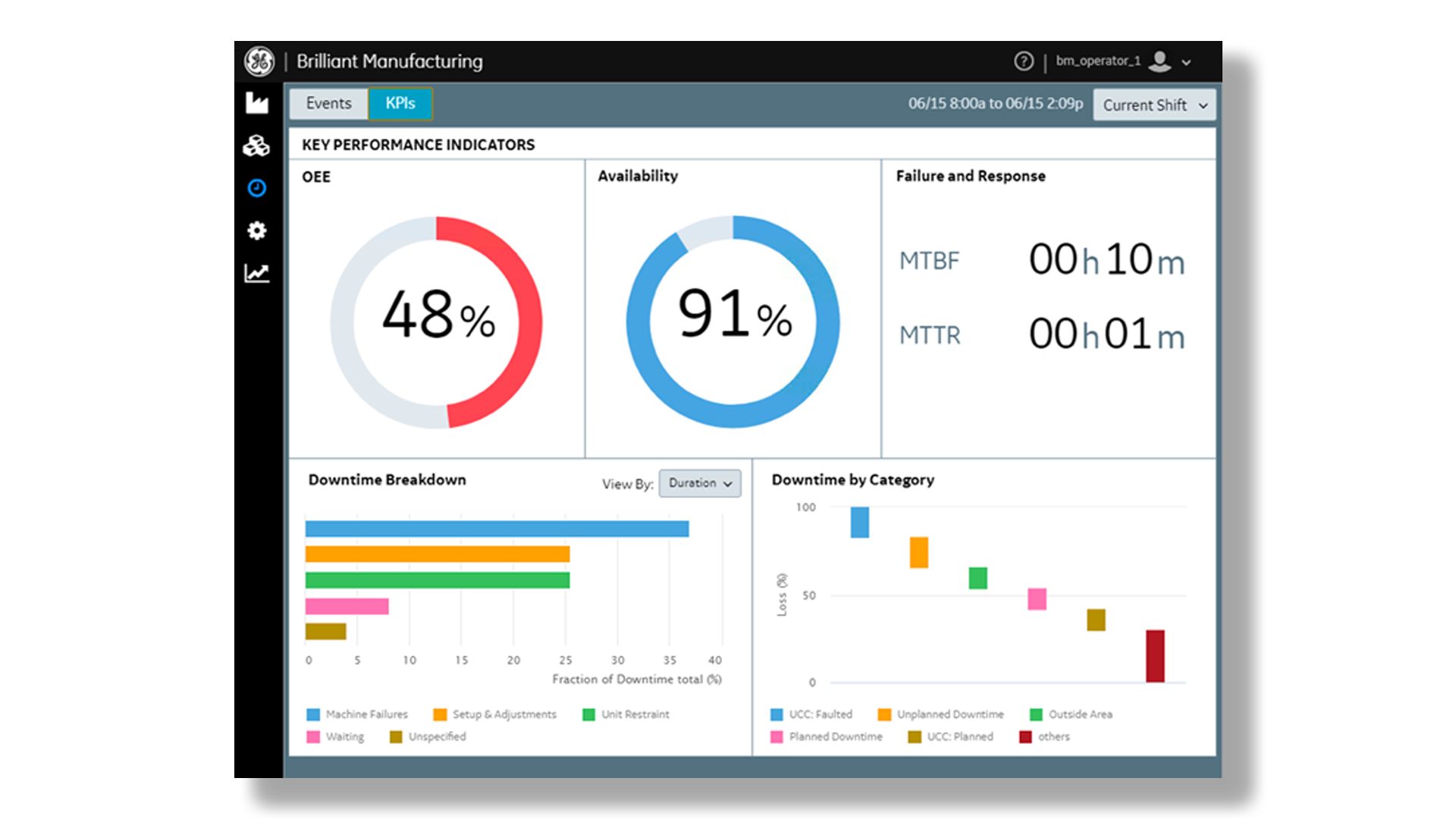

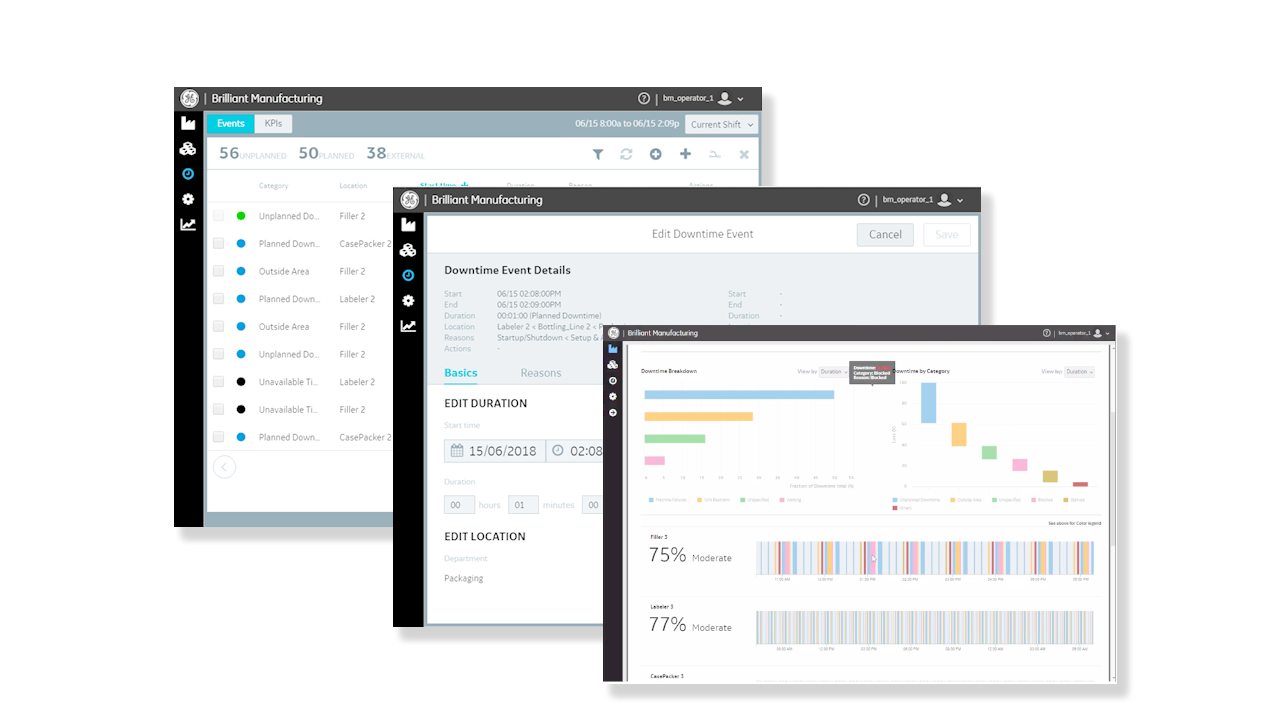

Actionable operational intelligence

With greater vision comes a clearer path forward. Understanding the challenges your operation faces are the first steps to profitable improvements. With accurate data and trends, decision making can be backed with real, actionable intelligence gathered from your operation. The next step of your journey begins with the right information.

Improve your operational performance

Unlock the true potential of your operation

Operational change always comes with associated costs. But if, in the long run, those changes prove profitable, it’s a worthwhile hurdle to jump. OEE systems with Astec Solutions provide you with the evidence required to identify pains and uncover their resolutions to the benefit of your manufacturing operation and your wider organisation.

World-class solutions

Plant Applications from GE Digital

Get in touch with our expert team today to learn more about how we can swiftly and painlessly integrate world-leading solutions with your operation. With minimal downtime, take your operation to the next level with Astec Solutions.

Outcome story from GE

As packaging is at the end of a highly specialized production process, flexibility is vital if Coloplast’s round-the-clock packaging operations are to keep running smoothly. Naturally, when short-notice shifts and unscheduled production halts occur during packaging, operators must respond immediately. With Proficy software automatically surveying every packaging step on every machine, problems can be identified and solved when they first arise, cutting response times to a bare minimum.