Smart people for smart manufacturing

Novotek Solutions has over three decades experience in delivering world-class manufacturing solutions to customers across a broad range of industries.

With an expert team, drawing from the experience of the entire Novotek Group, the future of your operation is in safe hands.

Whether you’re looking to enhance, upgrade or transform your systems, we’re dedicated to providing intelligent solutions to fuel your profitability and growth. Working in close collaboration, we ensure a perfect fit and desired outcomes in operation efficiency, flexibility and uptime to meet and exceed your objectives.

So, what are your operational ambitions?

Improve productivity and performance

Data is at the heart of digital transformation. Enabling the acquisition, analysis and accessibility of data alongside systems to synchronise people, processes, and equipment is vital in building an operation that’s fit for the future.

Increase visibility and improve operator decision making

With accessible and understandable data, displays and analysis, operators can take action quickly and more accurately. Right first time, with the correct information, means the mitigation and reduction of downtime.

Remove obsolescence and upgrade systems

It’s often comfortable to keep doing what we’ve been doing, but the truth is aging systems can hold operations back at best and present vulnerabilities at worst. Discover how we can make upgrades and remove obsolescence painless and profitable for your operation.

Streamline connectivity and remove information silos

Data is at the heart of digital transformation. Enabling connectivity across your sites, platforms and teams is a crucial step to reaping the rewards of digitalisation. With expertise and experience in DataOps, our team can guide you to the right solution to empower your operators and key stake holders to make the most of your data and unlock continual improvement.

Support and Maintenance Services

Flexible, always-on services for system support, patching, backups and more.

Our experience and expertise ensure your systems run smoothly. In the event of the unexpected, we’ll have you back up and running with the minimum of downtime and disruption.

Over 35 years of experience

Decades of experience across a spectrum of manufacturing industries allows Novotek to approach each project with a broad perspective. Highlighting and identifying opportunities to maximise your results while ensuring a cost-effective and robust solution. Our bespoke approach, backed by world-leading platforms, ensures your operation is fit for the future.

Novotek deliver expertly crafted solutions, tailor-made for your operation

Novotek Solutions Capabilities

Novotek Solutions has over three decades experience in delivering world-class manufacturing solutions across a broad range of industries.

With an expert team, drawing from the experience of the entire Novotek Group, the future of your operation is in safe hands.

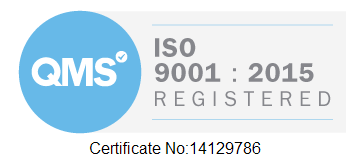

Quality & Security Assured

ISO establishes standards internationally agreed by experts. Novotek Solutions is registered for key standards in both Quality Management and Information Security Management

ISO 9001 : 2015 – Quality Management

Assures your solutions will be delivered to the highest standards of quality. The stringent framework of ISO 9001 provides increased efficiency, accuracy and customer confidence.

ISO 27001 : 2013 – Information Security Management

Compliance with this standard ensures the security of your information and data. Robust security policies are in place, with secure access management for peace of mind when exchanging information. The standard minimises risk exposure, providing confidence to our customers in our culture of security.