Ensuring reliable and consistent production operations can be challenging enough; as companies launch new products and formula variations, it gets harder. Proficy Batch Execution provides a framework that makes it easier to link formulas and recipes to the automation that drives your equipment -without each change requiring a mini-engineering project! Users maintain recipes and plant models in a software app; it then uses ISA-88 standards-based integration schemes to communicate key data to your control layer. So you get consistency without sacrificing flexibility. Originally designed with regulated industries in mind, it provides this structure in a package that can be deployed in accordance with regulatory requirements such as 21 CFR Part 11.

Recover Capacity With Batch Execution

Common challenges in batch-style manufacturing include regular mismatches of order quantities to equipment capacity, the need to avoid cross contamination, and (often) relatively fixed routes for material flows. It can be configured to automatically determine the routes and units that will allow for the most effective use of capacity. And the campaign management feature gives you ways of staging long runs of production, so cleaning and changeover operations can be minimised wherever possible.

An Intuitive View Into Production

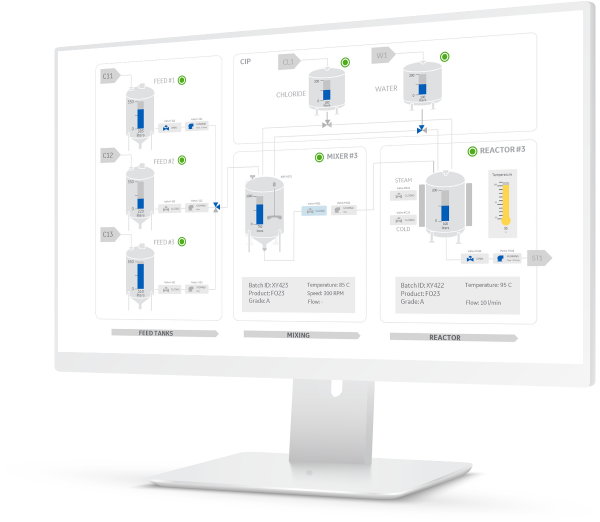

Proficy Batch combines a process flow style of visualisation with an asset-focused view that makes it easy for operators to see how production is going. And by putting a common operation-and-phase structure in place around recipes, the status views and reporting on operations are delivered using a consistent way of presenting information – making it quicker to spot problems or actions needed.

Integration With Existing Automation

Beyond the interface with PLC automation, Proficy Batch is designed to work with your HMI/SCADA. Users of Proficy iFIX can deploy pre-built views into their SCADA screens, so operators can have a single cockpit for a view of production progress and more detailed process monitoring. It can also incorporate information held in SCADA tags to stage and execute recipes, supplementing the data from your control system.

A Modern View Into Batch Operations

With GE Digtal’s release of Proficy Operations Hub, and the latest versions of Proficy Batch, you can bring recipe editing, process flow views, unit status and details and more into web-based apps and views. See the video below to see how you can make your window into Batch accessible through a browser, wherever and whenever your operators need it.

Core Functions

- Manage asset (unit) definitions and recipes in a user-friendly, code-free environment

- Set routing and usage rules to prevent contamination and maximise capacity usage

- Enable simpler programming methods for automation systems on core production assets

- Compile full logs of batch production activity, for easy reporting in the tool of your choice (MSSQL based Batch log)

- Standard Batch management and troubleshooting objects for deployment into HMI SCADA screens

- Supplement automated operations with Batch alerts and instructions for manual operator interventions

- Security and data management that can support 21 CFR Part 11 compliant deployments